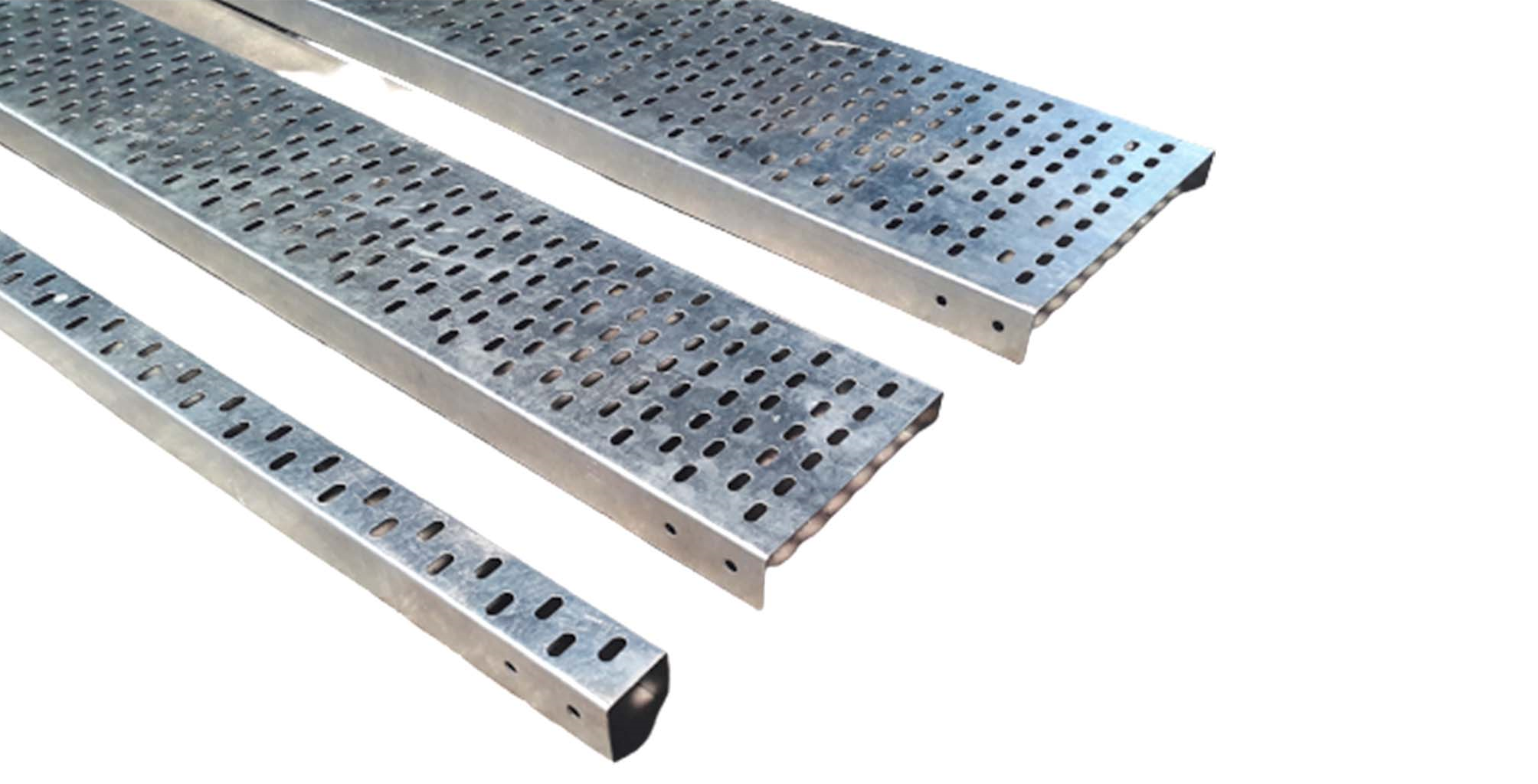

G I Perforated Type Cable Trays

Power cables, control cables, and instrumentation cables are all stored in traditional perforated cable trays. Excellent ventilation is provided by perforated cable trays, which also lengthens the life of cables and may be fixed to any building.

Cable Tray :

- Heavy duty power wires should be installed in big quantities using perforated types. Higher current flow can be achieved at the same cross section thanks to perforation, overheating and subsequent cable damage are prevented, and

easy cable tray connection thanks to coupling holes within are all made possible.

Uses of Perforated Cable Trays:

- Force and information cables and wires are supported by systems that include perforated cable trays. A perforated cable tray helps with overhauling, expanding, reconfiguring, or moving channels and supports and jams both force and sign links.

- The open design of perforated cable tray systems allows for powerful heat circulation as well as an easy path for replacement and repairs. Punctured link plate techniques are useful for underfloor use even though they are frequently attached to dividers or suspended from roofs.

Features of Perforated Cable Trays:

-

Sturdy design for moving a variety of cables.

-

The bases of perforated cable trays contain perforations that provide enough ventilation and provide a place to connect lines.

-

Because of the pre-aroused, hot-plunged powder coated, epoxy covered finishing, it is hostile to consumption, fire, and dampness.

-

Exceptional heat dispersion.

-

Cable lines are shielded by protected and smooth edges without any prior preparation.

-

Capable of withstanding short circuits adequately.

-

Available in every size.

-

Simple, quick, and adaptable establishment.

-

Unusual development configuration allows cable trays to be placed anywhere.

-

Available in various assistants to introduce and correct.

-

Easy to follow along with.

-

A long life span.